There is no doubt that a rigid box making machine is a must-have for any business that produces and sells boxes. With so many models available on the market, it can be challenging to choose the right one. Rigid box making machine is a type of machine used to manufacture rigid boxes. These boxes are then used to package and ship the product. There are many different types of rigid box making machines, each with its own features and benefits.

In this article, we will provide an overview of the different types of rigid box making machines available and their various advantages and disadvantages. We’ll also help you decide which machine is best for your customer’s specific needs. So read on to find out more!

1. What is a rigid box making machine and its types?

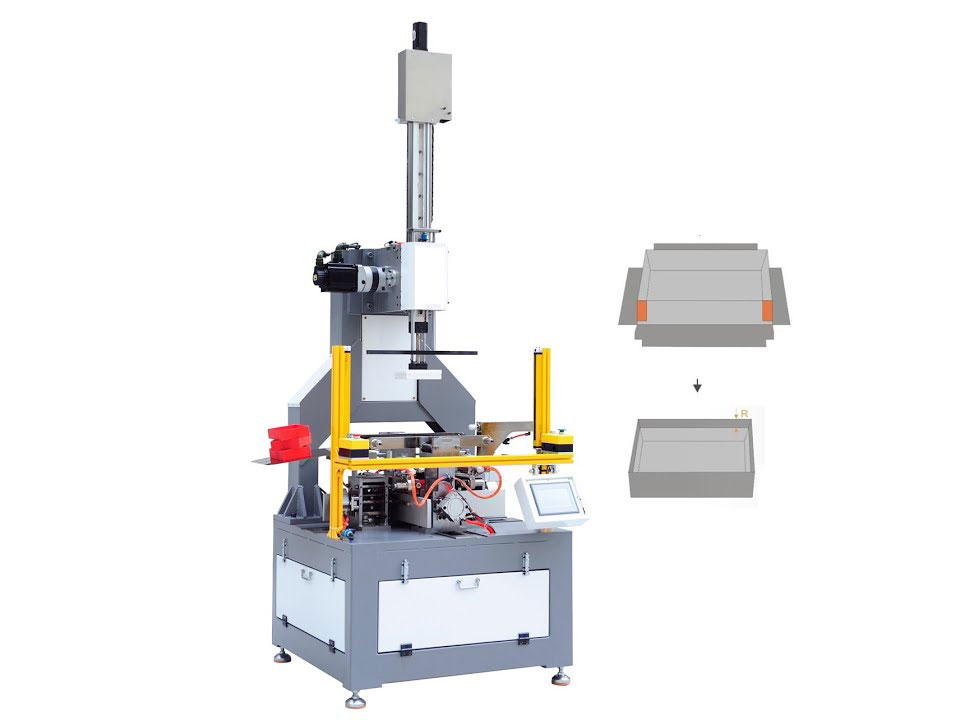

Rigid box making machine is a special equipment for making rigid boxes. These boxes are commonly used to package products such as electronic devices, cosmetics, and small appliances. Rigid box making machines are must-have equipment for any business that manufactures or packages retail products. Below are the different types of box making machines:

1) Automatic box making machine

Automatic rigid box making machines are the most commonly used type of machine in packaging operations. These machines can make boxes of any size and shape and can be programmed to create custom designs. Automatic rigid box machines are generally faster and more accurate than semi-automatic machines.

2) Semi-automatic box making machine

Semi-automatic box making machines are not as common as automatic machines, but they do have some advantages over automatic machines. Semi-automatic machines are usually less expensive and easier to operate than automatic machines. In contrast, semi-automatic rigid box making machines can create fewer custom designs than fully automated rigid box making machines.

3) Fully automatic box making machine

It is the most expensive type of rigid box making machine, but it is also the most automated. These machines can make boxes of any size and shape and can be programmed to create custom designs.

2. Different types of rigid box making machines and their average cost

The table below provides an overview of the different types of rigid box making machines and their average costs:

| Types of box making machines | average cost |

| Fully automatic box making machine | $50,000 – $100,000 |

| Semi-automatic box making machine | $20,000 – $50,000 |

| Fully automatic box making machine | $100,000 – $250,000 |

3. Working principle of rigid box making machine

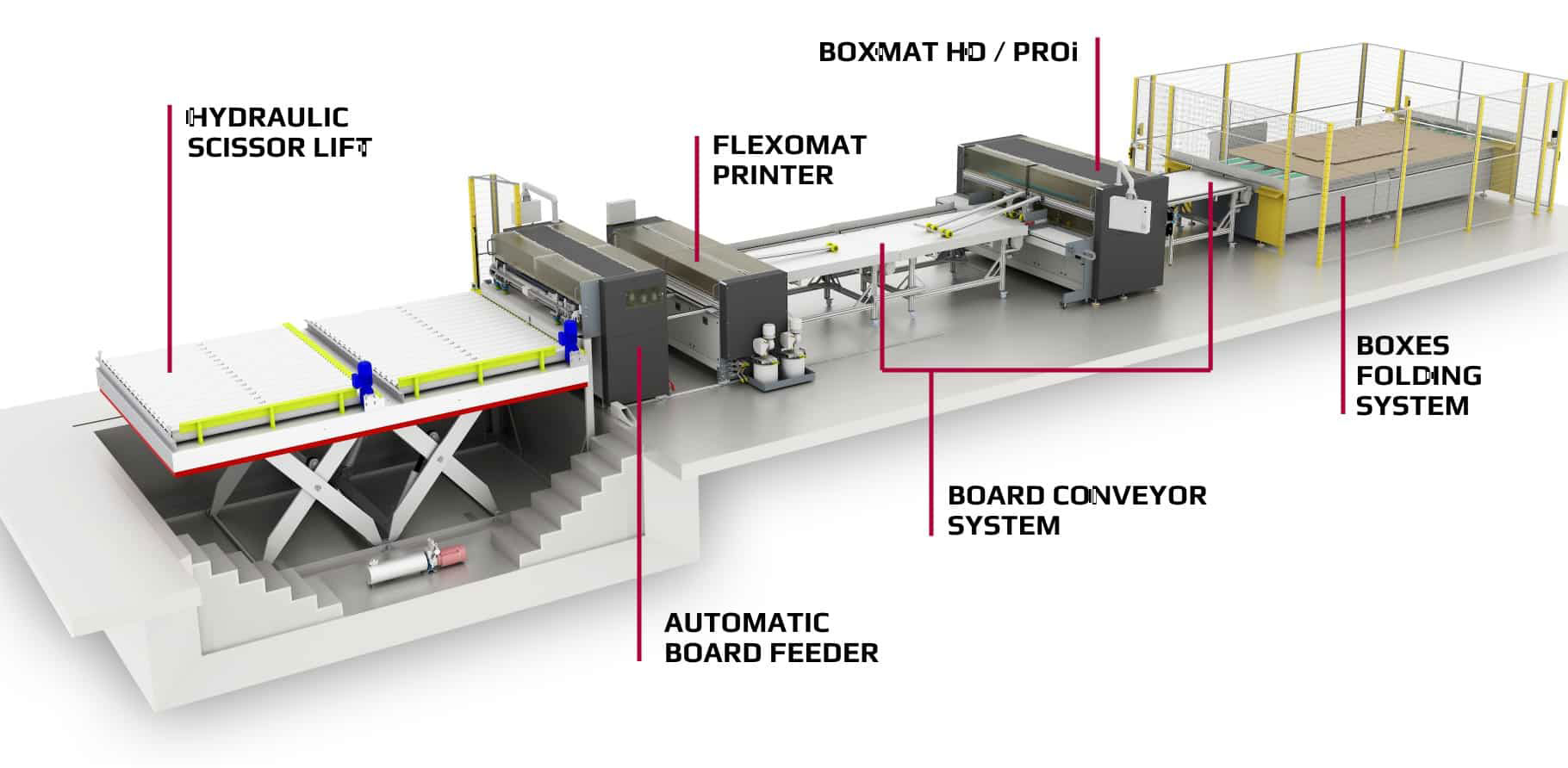

Rigid box making machine is a packaging machine used to manufacture rigid boxes. Ideal for high-end packaging applications, these boxes are used for a variety of products from cosmetics to electronic devices. Rigid box making machines are fully automatic and can produce high-quality boxes quickly. Here’s how a typical rigid box making machine works:

On the box material, the machine first prints your graphic design. The material will then be die-cut into a box shape. Once the box shape is cut, the machine scores and folds the box along the pre-determined crease lines. Finally, it will apply glue to the edge of the box and close it.

The entire process is automated and only takes a few seconds to complete. Rigid box making machines are highly precise and can produce consistent results time and time again. If your business requires high-quality rigid boxes, investing in one of these machines is a smart choice.

A rigid box making machine is a type of machinery used to manufacture rigid boxes. These machines are commonly used in the packaging industry and can be used to make a variety of different types of boxes.

4. The benefits of rigid box making machines for business

There are many benefits to investing in a rigid box making machine for your business. These machines help increase productivity and quality while also reducing costs. Here are some key benefits of investing in a rigid box making machine:

- Increase productivity: Rigid box making machines can help increase productivity by reducing manual labor. Businesses can save money and time by doing this.

- Quality improvement: Rigid box forming machines also help in improving product quality. This is because these machines are designed to produce products to a high standard.

- Cut costs: Rigid case making machines also help keep costs down. Due to their efficiency and cost-effectiveness, these machines are extremely popular. These are some of the major benefits that can be expected if you are considering investing in a rigid box making machine.

5. The cost of buying and maintaining the rigid box making machine

The cost of purchasing and maintaining a rigid box making machine can be high. Models and features of rigid box making machines will affect the initial cost. A basic machine can cost as little as $2,000, while a more advanced model with additional features can cost as much as $5,000.

While used rigid box making machines may be less expensive, it’s important to remember that these machines may require more maintenance and may not last as long as new machines.

Depending on the type of rigid box making machine purchased, the cost of maintenance will also vary. Here is a quick breakdown of maintenance costs for rigid box making machines:

- Cleaning and Lubricating – $50 to $100 per month

- Replacement Parts – $100 to $200 per month

- Electricity – $50 to $100 per month

As you can see, purchasing and maintaining a rigid box making machine can be expensive. However, if your customer is producing a lot of rigid boxs, the cost of the machinery will quickly be offset by the labor cost savings.

When considering the cost of purchasing and maintaining a rigid box making machine, it is important to consider the long-term costs as well as the initial purchase price. By doing this, you can ensure your customers get the best value for money.

6. 3 Tips for Effectively Using Rigid Box Making Machines in Your Business

As a business owner, you understand the importance of using high-quality packaging for your products. Rigid box making machines can help create durable custom boxes that protect items during shipping and storage. For example, I have a friend who is an iPhone wholesale supplier. When he shipped to customers, he used a custom-made rigid box for the iPhone. The quality of this rigid box is very good, not only to protect the phone inside from damage but also the appearance of the box is very beautiful.

However, it is very important to use the box making machine correctly to get the most out of it. Here are some tips on how to effectively use rigid box making machines in your customer’s business:

- Create a template: This will ensure that all boxes are the same size and shape, making for easier stacking and storage.

- Choose Durable Materials: The thickness of the cardboard and the type of glue used will affect the strength of the box. Make sure to choose a material that will protect the product from damage.

- Clearly label the box: Having a clear label on the box will help track inventory and ensure the product is properly identified when it reaches its destination.

By following these tips, you can use your rigid box maker to create high-quality, durable boxes that protect your products and help your business run smoothly. Making rigid boxes is an important step in ensuring your business’ success.

7. Rigid box making machine: maintenance and warranty

Just like any other piece of machinery, rigid box machines require regular maintenance and care to function properly. Here are a few things you need to keep in mind when it comes to the maintenance and warranty of your box making machine:

- Consult the manual: Always consult the manual that comes with your machine before attempting any type of maintenance or repair. The machine will be protected from any potential damage by doing this.

- Keep all parts clean: Make sure all parts and components are clean and free of debris. As a result, the machine will run more smoothly and efficiently.

- lubricate moving parts: Make sure to lubricate all moving parts regularly. The machine will last longer if this is done.

- Contact the manufacturer or a qualified technician: If you have any questions or concerns regarding the maintenance and warranty of rigid box equipment, always contact the manufacturer or a qualified technician for assistance.

By following these simple tips, you can help keep your rigid box making machine looking its best for years to come.

5. How to choose the right rigid box making machine for your business

Here are a few things you need to consider when choosing the right cap packaging machine. Here are some tips on how to choose the right rigid box making machine for your business:

- Size and capacity: It is important to consider the machine’s size and capacity first. Make sure the machine can handle the workload required by the customer.

- Material type: The next thing you need to consider is the type of material your customer will be using on the machine. Different machines are designed for different types of materials. Make sure to choose a machine that can handle the type of material your customer will be using.

- Cost: The last thing to consider is the cost of the machine. You need to make sure that the machine you get fits the client’s budget. There are a lot of different rigid box making machines on the market, so you want to make sure you take the time to compare prices.

These are just some of the things you need to consider when choosing the right carton making machine for your business. If you take the time to consider these factors, you will be able to find the right package for your client.

9. 5 Practical Tips When Buying a Rigid Box Making Machine

When you are in the market for a rigid box making machine, there are some key factors to keep in mind that will help you make the best decision for your business. Here are 5 practical tips to consider when buying a rigid box making machine:

1) Determine the type of rigid box

The first step is to determine the type of rigid box you need. Do you need a standard box or a custom box? Standard rigid boxes are less expensive and have shorter lead times. Custom rigid boxes are more expensive, but can be customized according to the specific needs of customers.

2) Consider enterprise size

The next factor to consider is the size of the client’s business. If their business is smaller, you may need a smaller rigid box making machine. However, if their business is large, you will need a larger rigid box making machine.

3) Know what the machine does

It is very important to understand the capabilities of a rigid box making machine before purchasing one. You need to make sure that the machine is capable of producing the type and size of rigid boxes your customers require.

4) Compare Price and Features

Once you decide on the type of rigid box making machine, compare the prices and features. There are a variety of rigid box making machines on the market, so it is important to find one that fits a client’s budget and needs.

5) Ask for a Demo

Finally, once you find a rigid box making machine that your client is interested in, ask for a demo. This will allow you to see the machine in action and make sure it is right for your customer’s business.

10. 7 Tips About Buying Rigid Box Making Machine From Chinese Suppliers

Here are some tips when you buy a rigid cover box making machine from Chinese suppliers:

1) Quality

When it comes to rigid box making machines, make sure you are getting one that is made from high-quality materials. This is important because you want your machine to last a long time.

2) Type

Another factor to consider is the type of rigid box making machine you need. There are several different types on the market, so be sure to choose the one that best suits your client’s needs.

3) Size

The size of the box making machine is an important factor to consider. Make sure the machine can accommodate the size of rigid box the customer wants to make.

4) Speed

The speed of the machine is another important factor to consider. Make sure that the machine can produce the number of boxes required by the customer in time.

5) Control Panel

A good control panel should also be included in the rigid box making machine. It is important that the control panel is easy to understand and use. It should also be able to provide you with all the information you need about your rigid box making machine.

6) Power

It is also important to have a good power source for the rigid box making machine. Make sure the machine can be plugged into a standard outlet. You should also make sure the machine has backup power in case of a power outage.

7) price

The price of a rigid box making machine is an important factor to consider. Make sure the machine you buy is within your budget. The machine should also be worth the investment.

These are just some of the things to keep in mind when purchasing rigid box making machines from Chinese suppliers. By taking these factors into consideration, you can ensure you are making the best possible purchase for your customers.

11. Conclusion

So there you have it. Everything You Need to Know About rigid box Making Machines! We hope this guide was helpful and that you are now able to make an informed decision about which machine is right for your needs.