Injection plastic molds are the foundation of modern mass production, enabling high-volume, high-precision plastic components to be made in any field from automobiles and pharmaceuticals to electronics and packaging. As China is the leading country in plastic injection molding exports, it is not only important for engineers, purchasers, and manufacturers who want to produce efficient plastic parts to find a suitable plastic injection molding service China supplier, but also an indispensable knowledge system for the design, manufacture, and maintenance of injection molds.

The following is the entire topic of plastic injection molds, from design and structure to production, maintenance, and what the future will hold.

1. What is a Plastic Injection Mold?

A plastic injection mold is one-use only equipment for forming hot plastic into precisely accurate three-dimensional shapes. Geometry of the part, surface finish, and tolerance are established by the mold, and rate of manufacture, part quality, and cost of manufacturing are established directly by the mold.

Typically constructed from hard tool steels or high-strength aluminum alloys, injection molds must withstand extreme pressures and thermal cycling throughout a series of injection molding cycles without deforming or weakening with time.

The integrity and life of a mold dictate the success of any injection molding operation, and therefore, mold design and production are critical stages of product development.

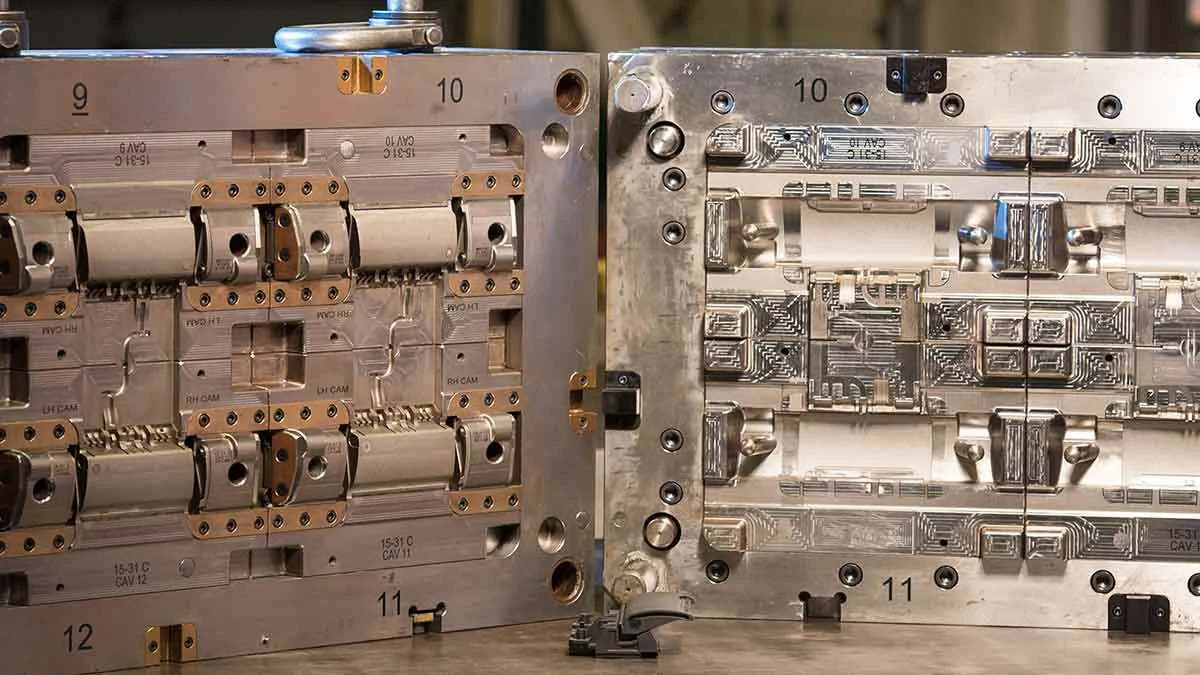

2. Basic Structure of an Injection Mold

All injection molds, regardless of complexity, contain the following structural elements:

1) Mold Base (Mold Frame)

Supports and retains the functional components of the mold. Standardized mold bases are cost-effective and make handling molds easier.

2) Core and Cavity Inserts

The core forms the interior surfaces of the part; the cavity forms the exterior surfaces. They control the shape of the part and are precision-machined to exact specifications.

3) Sprue, Runners, and Gates

Passages through which molten plastic travels to reach the mold cavity. Their design determines flow balance, cycle time, and quality of the part.

4) Cooling Channels

Channels through which coolant (typically water) circulates, regulating mold temperature for consistent cycle times and warpage prevention.

5) Ejection System

Made up of ejector pins, sleeves, and plates that push the molded item out of the mold as it hardens, reducing breakage of delicate features.

6) Venting System

Relief grooves, minor, for venting gases and air during filling cavities to avoid flaws such as burn marks or short shots.

Part accuracy and fit will determine mold efficiency, dimensional stability, as well as part appearance.

3. Plastic Injection Mold Types

Various project needs necessitate molds with varying types of configurations. Typical types include:

1) Cold Runner Molds

Simple and less expensive molds with plastic flowing through non-heated runners to cavities. Runners are typically trimmed and recycled after molding.

2) Hot Runner Molds

Use heated manifolds that keep plastic liquid in runners with no material loss and reduced cycle time. Higher capital investment but ideal production efficiencies.

3) Two-Shot (Multi-Material) Molds

Offer two different materials or colors of plastic molded into a single unit in one shot, incorporating function and beauty without further processing.

4) Stack Molds

Multiple cavity levels, higher output per cycle, without more machine space. Ideal for the production of small parts in high volumes.

5) Rapid Change Mold Systems

Modular molds for fast product changeover, minimizing downtime, and enabling flexible manufacturing for small batch sizes.

There are unique strengths and limitations for each type of mold based on application, volume of production, and part design complexity.

4. How Injection Molds are Made?

Injection mold making is an extremely accurate, multi-step process involving:

1) Steel or Aluminum Choice

Material selection considers strength, wear, heat transfer, and cost. Hardened steel such as H13 is employed in high-life tools; aluminum is typical for prototype molds.

2) CNC Machining

Computer Numerical Control machinery machines the steel blocks to precise core and cavity shapes by cutting, drilling, and milling.

3) EDM (Electrical Discharge Machining)

For tough-to-machine areas and small features, EDM molds fine details on hardened steel.

4) Heat Treatment

Steels are hardened and tempered to ultimate toughness without sacrificing final finish machinability.

5) Surface Finishing and Polishing

Surface finishing is applied to mold surfaces to create required part texture—high-gloss mirror to rough textures—depending on part cosmetics and functional needs.

6) Assembly and Testing

All mold components are built, fitted, and tested with mold trials to provide dimensional integrity, venting, cooling performance, and cycle efficiency prior to full-scale production.

A well-crafted mold gives effective molding, good parts, and extended mold life.

5. Mold Life Expectancy and Maintenance

Mold life is an important consideration in the economics of a project. Common mold life ranges are:

- Prototype Molds: 500–10,000 cycles

- Low-Volume Production Molds: 10,000–100,000 cycles

- High-Volume Production Molds: 100,000–1,000,000+ cycles

Mold life depends on material selection, part complexity, operating conditions, and maintenance quality.

Preventive Maintenance—periodic cleaning, lubrication, wear inspection, and cooling circuit maintenance—increases mold life, maintains part quality, and prevents costly unplanned downtime.

Neglect of maintenance decreases mold life significantly, causes repeated defect formation, and increases long-term operating expenses.

6. Key Factors Affecting Mold Cost

The cost of an injection mold is very dependent upon:

- Part complexity: More complex parts require more complex, time-consuming molds.

- Cavity number: Multi-cavity molds offer maximum production but significantly contribute to design and build effort.

- Mold material: Hard steel molds are more costly but have longer life; aluminum molds are less expensive but have shorter life.

- Tolerance requirements: Larger tolerances demand more precision machining and inspection work.

- Surface finishes: Gloss or textured finishes demand high-level polishing or specialty surface coating.

- Other options: Hot runner systems, foldable cores, or side actions increase design complexity and cost.

Accurate estimation of mold cost at the planning stage avoids surprise project costs and allows for wise purchasing decisions.

7. Future Injection Mold Technology Trends

Improvements in mold technology are revolutionizing potential for production:

1) 3D-Printed Mold Inserts

Additive manufacturing allows for the production of complex cooling channels and rapid prototype molds with lower expenditures.

2) Conformal Cooling

3D-printed internal cooling circuits closely follow part geometry, minimizing cooling times, cycle times, and warpage.

3) Modular and Rapid Tooling

Prealigned mold bases with interchangeable cavity inserts reduce tool changeovers and support rapid manufacturing.

4) Smart Molds

Real-time temperature, pressure, and strain sensing in molds supports predictive maintenance and quality inspection.

Breakthroughs in molds enhance productivity, reduce cost, and introduce new design opportunities, positioning injection molding more competitively in an evolving marketplace.

8. Conclusion

Plastic injection molds are the key assumption of successful, high-quality mass production. Control of the mold design, diversity, production methods, maintenance, and cost controls needs to be exerted in an endeavor to yield successful outcomes in new plastics production.

With advancing technology, knowledge, and capitalizing on improvements in mold design and buildout will increasingly position the vanguard manufacturers ahead of everyone else. Spending money on quality mold solutions is not an investment—it’s a move in the right direction toward duplicable, long-term prosperity.