Graphic overlays are thin film graphics layers used in product design and use. Overlays are usually printed subsurface, meaning their ink layer is protected from being worn off from everyday use by being covered with transparent material printed over it. Machines used on an ongoing basis must be protected from their environment. Whether in an industrial plant or emergency department setting, your equipment plays an integral part of everyday operations and must therefore be safeguarded accordingly. There are two primary methods of protecting electronic devices: panel covers and overlays – each offering their own distinct benefits but generally speaking, graphic overlays tend to be preferred over panels.

This article will address the value of graphic overlays across a range of industries and their pros and cons so readers can gain a clearer grasp on this application’s special characteristics.

1. Elements of graphic overlays

As we consider the components that comprise a graphic overlay, here is some additional information that may assist us with choosing an ideal construction. A graphic overlay typically comprises:

1) Base material

Most common substrate materials include polyester, polycarbonate, acrylic, and PVC materials when graphic overlay manufacturing. The reason industry utilizes polyester extensively is that it is solvent, chemically strong, abrasion and scratch resistant, and polycarbonate provides enhanced flame retardance at a low cost. Polyester coverings tend to be considered more durable; often found in medical, industrial plant environments, and home appliances, while polycarbonate offers more appearance options while remaining thick and sturdy enough for daily use.

2) Printing

Selecting an effective printing technology is key to producing outstanding graphic overlay production results. Screen, digital, and offset printing all have specific advantages tailored to meet specific design requirements and production capacities; screen printing stands alone due to the heavier ink deposit, which creates longer-term resistance, with minimal fadeout over the long term.

Digital printing is the only one which is flexible and adaptable, having the ability to modify designs in real-time, along with a set of colors and graphics options to accommodate designs in real-time. This makes digital printing ideal for creating intricate overlays. Furthermore, its precise color matching and excellent detail rendering capabilities enable high-quality finishes and fine craftsmanship in each piece printed digitally.

3) Adhesive

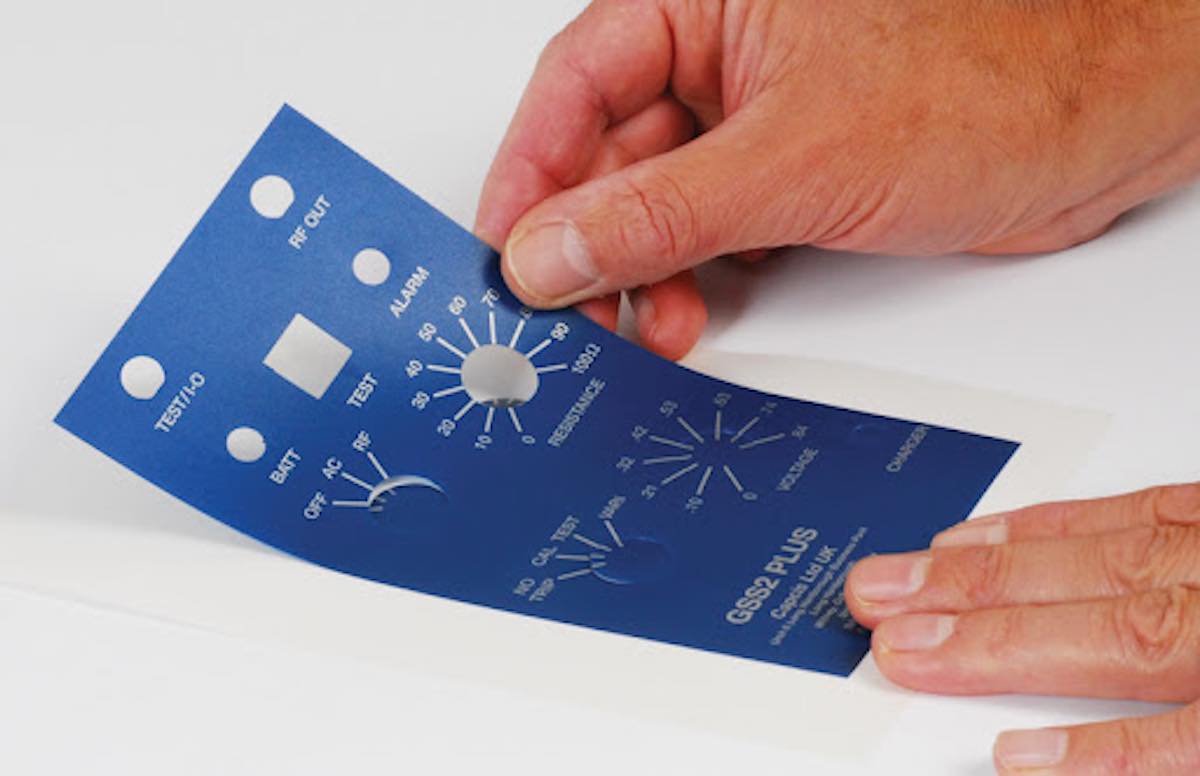

Adhesives play an essential part in the final shaping and lifecycle of graphic covers. Before choosing one to use, it’s important to consider some key questions about its application – flat or curved surfaces for application equipment and instruments?, temperature and humidity of use?, influences of chemical dust particles?. A suitable adhesive should adhere strongly without altering athe ppearance or performance of the cover layers.

As well as these three main elements, there are also various other variables which vary with use and purpose, including relief characteristics of buttons, cutouts, background lighting effects and embossing options. Suppliers will offer relevant options during design and production.

2. Advantages of graphic overlays

Graphic overlays have become an indispensable design element in modern devices, due to their distinctive functionality and aesthetic benefits. Here are their advantages:

1) Enhance user experience

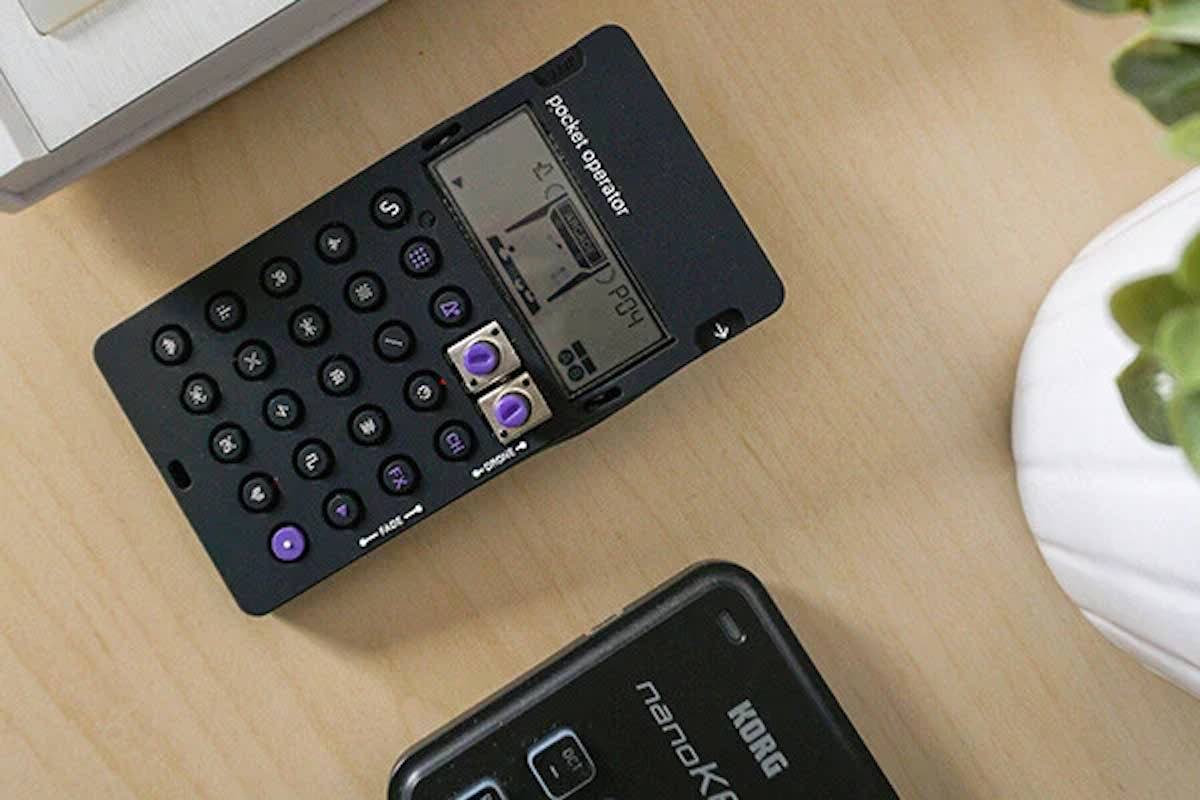

Graphical overlays offer many advantages to enhance user experiences. With visually appealing yet intuitive interfaces that guide users in operating electronic devices, well-designed graphical overlays with clear symbols, buttons and instructions can greatly decrease errors while increasing overall satisfaction, helping people communicate or operate devices more efficiently than before.

2) Durability and protection

Graphic overlays are an essential part of the protection of underlying electronics. Constructed from robust materials like polycarbonate and polyester, they shield units from environmental factors like dust, water, chemicals and abrasion – the secret to long term reliability in harsh or harsh environments.

3) Customization and branding

Customization is another key benefit of graphic overlays for manufacturers. They can customize designs, colors, logos and text to reflect the spirit of their brand’s image – not only is this great for aesthetic purposes but it strengthens brand loyalty as well. Manufacturers can tailor each graphic overlay design to their product perfectly while standing out among crowded markets by creating customized user interfaces that showcase each brand.

4) Cost-effective solution

Graphic overlays offer an economical alternative to traditional panel covers, making them a smart choice for enhancing electronic devices. Their production requires less intensive design and construction work, thus helping lower overall costs. Furthermore, overlays are usually made out of more affordable materials compared to those typically employed when crafting traditional panel covers.

Their installation cost is also minimized because of the way they can be easily applied using adhesives instead of through complex mounting procedures. Also, advanced manufacturing techniques like screen printing and digital printing enable mass production while maintaining low production costs.

Graphic overlays provide balance between cost effectiveness and flexibility and therefore constitute a best match for the majority of applications ranging from consumer goods to industrial equipment. With their ability to provide high performance at less cost, graphic overlays perfectly meet cost and performance requirements for both manufacturers and users.

5) Functional improvements

Graphic overlays not only provide protection and aesthetics to electronic equipment, but can also enhance their functionality by providing features like backlighting, tactile feedback and transparent windows for display and indicators to graphic overlay designs. They are thus able to create more efficient friendly interfaces so that they are able to operate the device more efficiently.

6) Easy to maintain and replace

Graphic overlays are created to be durable yet easily replaceable if damaged over time, providing easy maintenance for electronic devices without major repairs or replacement costs. Furthermore, being able to update overlay designs allows companies to implement new features or brand changes without incurring major hardware changes.

3. Notes on Graphic Overlay

Graphic overlays offer many advantages, yet proper care must be taken during the design and material selection stages to minimize potential issues. Below are several precautions you should keep in mind for optimal use:

1) Replacement for damaged overlays

Graphic overlay damage typically demands more severe repair, and in some situations, replacement can even be required, resulting in unforeseen downtime and additional cost, particularly for custom overlays. Preventing damages through proper handling and selecting durable materials during design phases may help address such concerns.

2) High initial installation cost

Graphic overlays are cost-effective long-term investments but can be costly to install in the first place for small organizations due to design, prototyping, and setup charges involved in production processes. Therefore, organizations must plan their budgets well so that any investment aligns with operational needs and size.

3) Environmental considerations

Graphic overlays that are subject to harsh environmental exposure, such as direct sunlight, intense heat or UV light, over a period of time can become compromised, risking warping coverings or defective adhesives, losing functionality entirely, or being damaged over time. To prevent this issue from arising again, it is advisable to use high-UV and heat-resistant materials, especially for outdoor or industrial use.

4) Impact of inferior adhesives

Poor-quality or inadequate adhesive can compromise the mounting of graphic overlays, leading to functionality failures and possible equipment failure. Over time, poorly mounted overlays will detach, necessitating costly repairs or replacements; manufacturers must ensure proper use of high-grade adhesives with precise application to maintain their overlays reliable and long-lasting.

By incorporating a focus on such important considerations throughout the design, material selection, and installation stages of graphic overlays, companies can best lengthen their lifespan and functionality and decrease risks and expenses.

4. Conclusion

Graphic overlays are integral parts in most devices. They improve functionality, aesthetics and durability and protect sensitive components, while strengthening branding – making products more appealing and reliable. Applied either to industrial equipment or consumer electronics products, graphic overlays extend product life while improving user interaction, especially because high-quality materials ensure longer-term performance at lower maintenance costs.