A drop testing machine is a common laboratory testing machine in the paper and packaging industry. Testing different aspects of a product is crucial to ensure that customers do not face any product rejections in the future. When corrugated boxes or cartons are dropped from a certain height, it will cause damage to the product’s quality. Therefore, reliability test equipment manufacturers have designed a high-quality laboratory testing machine called a drop strength tester to test a carton’s ability to drop and determine the shipping value of the material.

In this blog, we will give you brief information on the different factors you must consider when choosing the best drop tester for your packaging needs. We will also discuss an introduction to different drop test machines. This guide will help you choose the best drop test machines for your needs.

1. Why is it important to test the drop strength of corrugated boxes?

Corrugated boxes are one of the most commonly used packaging materials as they provide protection for a variety of products that need to be transported and stored safely. However, to ensure your corrugated boxes perform as intended, you should always test them for drop strength before they leave your facility.

Manufacturers will implement the corrugated box drop strength test method to test the durability of the material when dropped from a certain height. This testing is important because it can help ensure that the box will protect its contents from damage during shipping and handling. But did you know you can quickly carton drop test your packages with a drop tester? Let us discuss the brief information about the drop test machine.

2. What is Drop Testing Machine?

The drop testing machine is a laboratory testing machine used to test the drop capability of cartons and to simulate the effects of shipping and handling on the product. This quality lab testing machine is designed to determine the shipping value of a package from 9 different angles.

This quality laboratory testing equipment is used in several industries including paper and packaging, pharmaceuticals, PET and bottles, and more. The manual model of this quality inspection equipment is designed with an angle drop device that helps in the accurate shipping of packages by thoroughly testing packages from different angles.

With this single laboratory testing machine, materials will be subjected to straight line and angle drop tests. You also learn about the importance of drop testing in the packaging industry. Now, let’s discuss the brief information on different types of drop testers.

3. Different types of the drop test machine

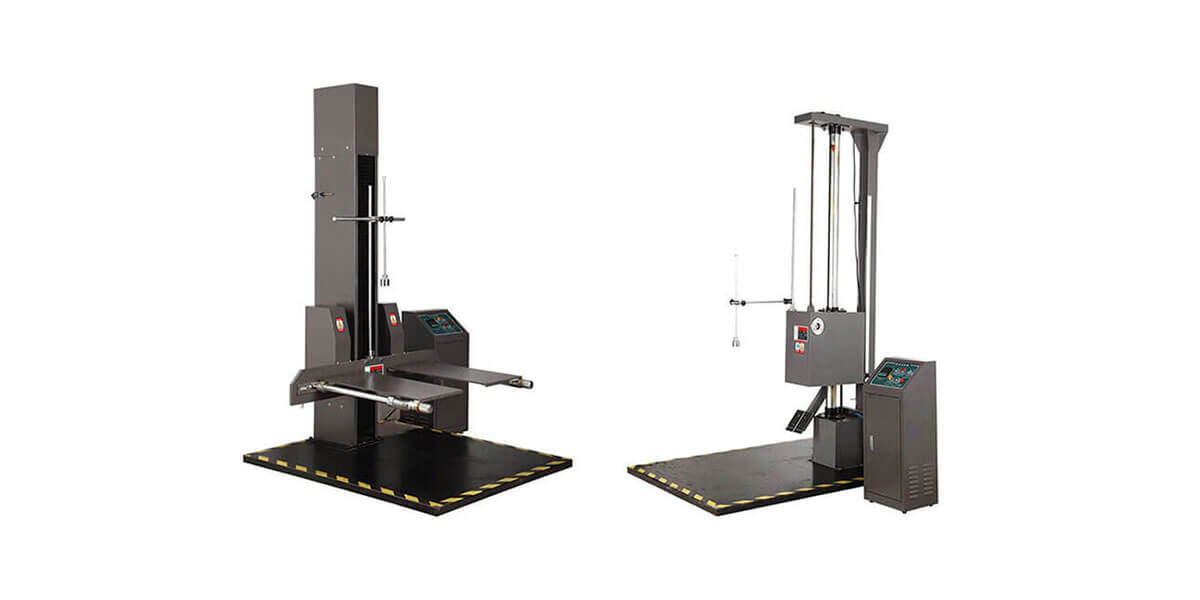

Usually, manufacturers offer several models of drop testing machines, from manual to pneumatic. The drop test standard is designed to lift the test platform through the guide mechanism, and the pneumatic model of the drop strength tester is equipped with a wired remote control mechanism to eliminate human interference.

Let’s discuss brief information about these two models:

1) Drop test machine manual model:

The drop testing manual model is designed according to the IS:7028 Pt IV mechanism and can be used to determine the shipping value of parcels and containers. The manual drop tester is an important laboratory testing machine designed with an angled drop arrangement that helps to accurately test packages from all angles. This is critical to ensuring that the packaging can withstand the rigors of shipping and protect its contents. The tester is easy to use and provides reliable test results.

Below we list the features of this quality testing equipment:

- Provide a test platform for improvement through the guiding mechanism

- Drop Height Adjustable Clamp

- Straight line and angle drop tests can be performed on one machine

- Robust chassis with solid construction

- easy to use

- Comes with user-friendly controls

2) Drop testing machine electro-pneumatic:

The drop test machine is the perfect machine to test the drop strength of corrugated boxes. In order to eliminate human interference, it is equipped with a wired remote control mechanism. The machine can be programmed to drop cartons from a predetermined height at a specific rate. The results of this test can be used to assess the strength of the carton and make necessary changes to the design.

Below we list the electro-pneumatic features of the drop testing machine:

- Top edge fixtures that can be adjusted in height according to test requirements

- It comes in a Havel gray and blue combination with a zinc chrome finish for corrosion protection.

- The body is made of mild steel for extended shelf life

- it has twin flaps as a landing platform

With these high-end features, manufacturers in various industries can drop test materials to ensure quality products are delivered to customers. Now, let’s briefly discuss the factors that must be considered when choosing the best drop tester for your industry.

4. Factors to Consider When Choosing Drop Testing Machine

There are a few main factors to keep in mind when considering the type of drop testing machine to use for testing purposes. From machine accuracy to robust construction and measurement angles, you can consider different factors when determining a material’s drop strength. The following factors should be considered when choosing a drop-strength tester:

1) Design and Construction:

Design and construction are considered important parts of quality control, helping manufacturers determine whether a machine will last. That’s why designed drop testers to feature mild steel powder-coated, corrosion-resistant bodies with ergonomic aesthetics. Its sturdy platform base with extended load capacity allows manufacturers to easily perform drop strength tests on materials.

2) Calibration:

Calibration is the process of setting up the machine accurately so that the user obtains highly accurate laboratory test results. A drop testing machine often offers easily calibrated laboratory test machines with NABL-accredited calibration reports (traceable). This means your machines should have been tested and certified to meet specific precision standards.

3) Easy to operate:

Another important factor is the ease of operation. You want to make sure the drop testing machine you choose is easy to operate so you can get the most out of it.

4) Drop height

The drop height of the material can be taken into account when buying a drop test machine. The manual drop strength tester has a minimum drop height of 770mm (0.75m) and a maximum drop height of 1800mm (1.8m).