Brass and stainless steel are the main metal ball valves. They are used in many piping applications to regulate the flow of media through them. Stainless steel is an alloy of iron mixed with chromium and nickel, while brass is a mixture of copper and zinc. When choosing the perfect valve type for a specific project, it is crucial to understand brass ball valves vs. stainless steel ball valves because of the differences in materials and costs. Deciding between the two can be difficult, but the task can be made easier by considering the applications they require.

So, without further ado, let’s get started!

1. Everything you need to know about brass ball valves

The following is relevant knowledge about brass ball valves.

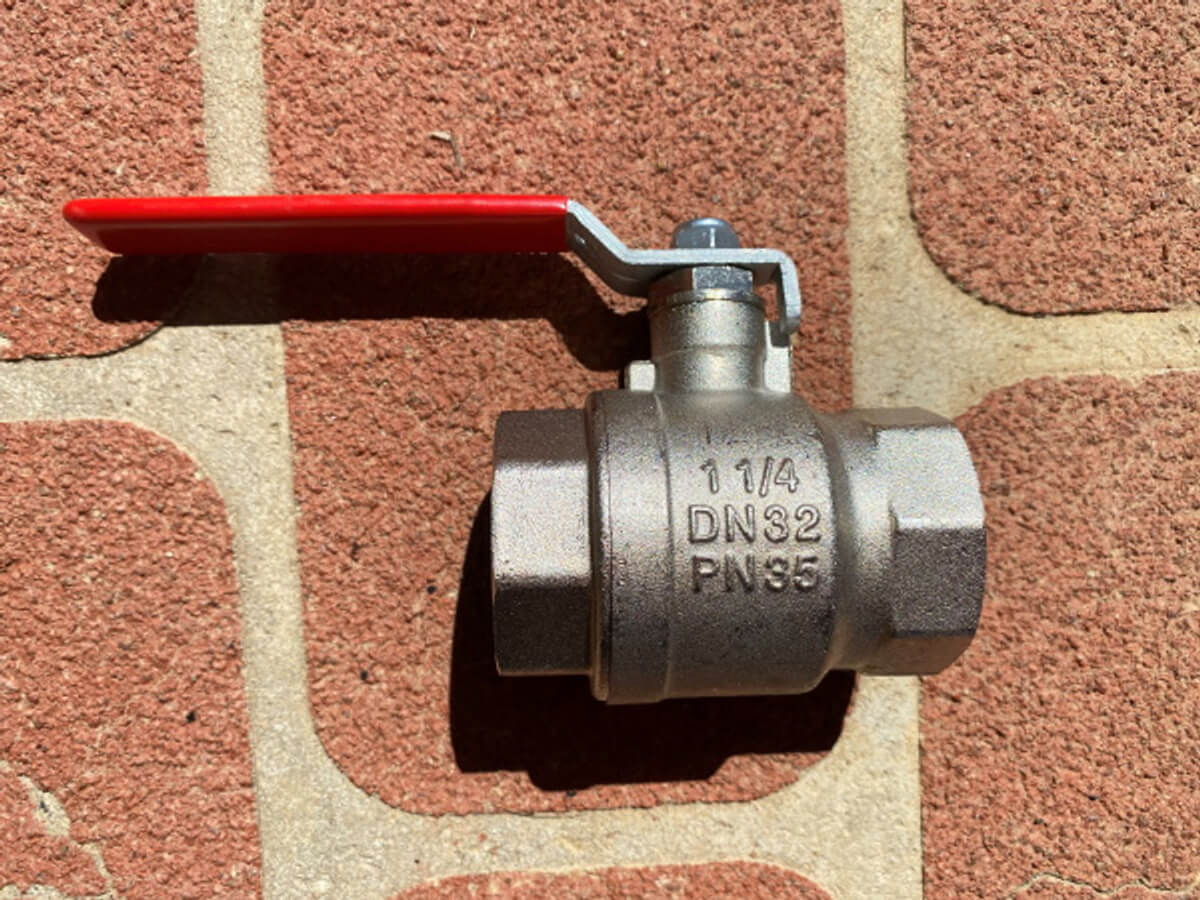

1) What is a brass ball valve?

Ball valves can also be made from brass, a metal composed of copper, zinc, and occasionally other metals. Brass ball valves may contain small amounts of lead (usually less than 2%). However, due to the potential health risks posed by lead, the U.S. Lead-free brass ball valves are the only ones approved by the Food and Drug Administration (FDA).

The first component to fail in a metal ball valve is almost always the soft seal. This means that in most applications, a brass ball valve will last just as long as a stainless steel ball valve before starting to leak. If your application does not require a corrosion-resistant metal, brass will provide the same service life as stainless steel.

Additionally, brass ball valves accept welding more readily than stainless steel, making brass a more versatile choice in certain industries and applications. One of the most commonly used materials in piping applications is brass. Valves made from it purchased from Chinese valve manufacturers are relatively easy to use and even install. They have the best corrosion resistance and are much softer than stainless steel, which makes sealing easier.

When sealing valves made of materials other than brass, specific duct tape or thread sealant is required. But brass sealing products are more suitable and easier to use. Some lead-free options run the risk of lead contamination if corroded. But if the brass valve isn’t part of your drinking water system, it’s not a big deal.

It’s worth noting that the amount of lead a brass may release is directly related to its zinc content – the more zinc the valve contains, the more lead will be released. Brass ball valves are suitable for well and pipeline applications and are divided into three-way brass ball valves and forged brass ball valves.

2) Advantages of using brass ball valves

- Oil and gas valves made of brass are ideal for pipeline applications.

- They come in two types: leaded and lead-free. If working on a drinking water system, lead-free valves are a better choice.

- They are a more cost-effective option than similar products and include several important features.

3) Disadvantages of using brass ball valves

- Brass valves are more susceptible to corrosion than stainless steel valves.

- These devices are not suitable for use in saltwater environments.

- Some lead-free brass options run the risk of contamination if they rot.

4) Application of brass ball valve

In most applications, a brass ball valve will provide the same performance and service life as a stainless steel ball valve. However, in applications with very extreme pressure or temperature requirements, stainless steel or other more durable materials may be more suitable. Having said that, the soft seal, usually made of PTFE, is still the weakest link. This means that these extreme applications also require specialized sealing materials.

There are a variety of applications for brass ball valves, including residential and commercial plumbing, water wells, HVAC, and many others. Certified lead-free brass ball valves must be used in certain applications, such as those involving drinking water or food processing, to meet FDA regulations.

Bottom line: Brass ball valves are the more economical choice as long as no highly corrosive materials are flowing through the valve.

2. Everything about stainless steel ball valves

The following is relevant knowledge about stainless steel ball valves.

1) What is a stainless steel ball valve?

Stainless steel is a resilient metal made from an iron alloy combined with chromium and nickel. This durable material is ideal for closure and control applications, as stainless steel ball valves are known to effectively prevent leaks, withstand a wide temperature range, and perform well under high-pressure conditions.

Stainless steel ball valves are a long-lasting choice even when used in highly corrosive environments; 316 stainless steel is an especially corrosion-resistant alternative that contains more nickel than standard stainless steel, as well as added molybdenum (a chemical with a very high melting point silver metal). This combination makes the 316 stainless steel ball valve more resistant to chloride and therefore ideal for applications in marine environments.

These valves are best suited for residential and commercial applications and offer excellent versatility. But there’s more to know about brass and stainless steel ball valves than their uses. A stainless steel ball valve that can be quickly closed by rotating 90 degrees and with low torque. Its perfectly equal inner cavities provide straight flow paths with low media resistance.

Despite its compact structure, it is easy to operate and maintain. It is ideal for controlling the flow of various media types such as air, water, steam, and corrosive media including oil, mud, and radioactive and liquid metals. The valve body of the stainless steel ball valve can be integral or combined. But it is generally installed in a horizontal position in the pipeline.

2) Advantages of using stainless steel ball valves

- These valve types are very durable and can work for a long time.

- Stainless steel valves are superior to other metals in terms of temperature resistance and pressure rating.

- They are corrosion-resistant and suitable for use in seawater and commercial brewing systems.

- Stainless steel valves require minimal maintenance than similar valves.

3) Disadvantages of using stainless steel ball valves

- Stainless steel ball valves are more expensive, which makes them a disadvantage.

- Equipment made from this stainless steel tends to be slightly heavier than other materials. Therefore, if weight is an important factor for any project, using these valves may not be a good choice.

4) Application of stainless steel ball valve

Stainless steel ball valves are frequently used in industrial processes, manufacturing, and construction because they are resistant to corrosion, high temperatures, and high-pressure environments. The following are some of the most common applications for stainless steel ball valves:

- Petroleum refining

- Offshore operations

- brewing system

3. Brass vs. Stainless Steel Valves: Which is Better?

For some reason, there are many differences in the quality of brass valves and stainless steel valves. While brass is an excellent general-purpose metal that can be used for a wide range of plumbing jobs, stainless steel has other applications that may make it a better choice.

A stainless steel valve is much more corrosion-resistant than a brass valve, for example. In fact, this is the main reason why these components are approved by the FDA for handling food and beverages, while brass valves are not.

However, this does not mean that it is immune to corrosion. Different types, such as those that cause red stains or greenish-blue stains on the surface or those that cause leaks, can still affect stainless steel valves. Stainless steel valves also last much longer than brass valves and can withstand higher temperatures.

Brass valves, on the other hand, are the preferred choice for many residential and commercial plumbing systems. It is also a better choice for welding, which can reduce labor costs and project duration.

Because brass or stainless steel valves have different advantages and disadvantages, one cannot be objectively considered better than the other.

This table compares Brass vs. Stainless Steel Ball Valves so you can choose the best ball valve for your needs.

| basis of difference | brass ball valve | Stainless steel ball valve |

| Material | Brass ball valves are a copper alloy in which copper and zinc are occasionally mixed with other metals. | Stainless steel ball valves are an iron alloy of nickel and chromium. |

| Cost | Brass industrial ball valves are less expensive than stainless steel ball valves. | Stainless steel ball valves are more expensive than leaded and lead-free brass ball valves. |

| Softness | Brass is softer than stainless steel, so it seals more easily than stainless steel valves. | Stainless steel is more challenging than brass, making it more difficult to seal than brass valves. |

| Product availability | Products for sealing brass ball valves are more readily available than products for sealing stainless steel ball valves. | Products used to seal stainless steel ball valves are more challenging than products used to seal brass ball valves. |

| Welding | Due to its chemical composition, brass is better suited for welding than stainless steel. | To weld with stainless steel, its oxide layer must be broken down frequently. |

| Corrosion resistance | Brass valves are more resistant to corrosion than plastic valves. | In terms of corrosion resistance, especially in marine environments, stainless steel is preferred. |

| Durability | In harsh water environments, valves made of brass are not a good choice and have poor durability. | Stainless steel valves perform better in harsh water environments, ensuring the valve is more durable. |

| Pressure Level | These valves have a lower pressure rating compared to stainless steel, making them less tolerant of high pressures. | Brass valves have a lower pressure rating than these valves. Therefore, they are more resistant to high pressures than brass ball valves. |

| High-temperature resistance | For high-temperature applications, brass ball valves are not the best choice. | Stainless steel can operate at higher temperatures and last longer than brass. |

| FDA approved | The FDA does not approve brass ball valves unless they are certified lead-free, as this makes them unsuitable for use in the food industry. | FDA approves stainless steel ball valves for use in the food industry. |

While both types of valves are excellent choices for pipeline jobs, they have some differences that make each valve perform well under different conditions.

4. Conclusion

Don’t forget to consider these factors when choosing the ideal valve material for your next project. It is also important to conduct in-depth research on the industry, requirements, and materials of the project. Additionally, if the application requires higher corrosion resistance, use a stainless steel system.

Anyone wanting high-quality stainless steel and brass ball valves should contact Plumberstar. This blog will help everyone choose the perfect material for their plumbing system as it is a big responsibility. All of the factors listed above, including price point, durability, resistance, and safety, will help make a tough decision about the best component for a specific application.