Valves are a critical component in industrial systems. Whether regulating fluid flow, gas pressure, or automated processes, valves perform crucial tasks in industries from oil and gas to water treatment, HVAC, food processing, and pharmaceuticals. But the correct type of valve is only half the answer. The functioning of your system also depends upon selecting the correct supplier—one that is able to meet your technical specifications, ship when scheduled, and provide long-term support.

This guide addresses the process of selecting a valve supplier that is not just a seller of the product, but a strategic business partner. Unlike the previous articles addressing valve customization, this article addresses supplier selection criteria, risk mitigation, and establishing a relationship, without repeating information on design or specification requirements.

1. Why the Right Valve Supplier Makes a Difference

Industrial process failure can be expensive. A valve failure can result in:

- Process downtime

- Safety incidents

- Product line contamination

- Regulatory non-compliance

- Financial loss and reputational damage

A good valve supplier reduces those risks by providing:

- Quality assurance and certified manufacturing

- Prompt and accurate communication

- Dependable availability of spare parts

- Problem-solving engineering expertise

- Scalable solutions as your company grows

Your supplier selection impacts not only procurement, but also efficiency, safety, and business continuity.

2. Start With a Clear Concept of What You Require

Define your expectations prior to comparing suppliers. This will save you time from evaluating vendors who are not able to meet your operational or compliance needs.

1) Define the Scope of Supply

Do you need:

- General-purpose valves (off-the-shelf)?

- Specialty valves (e.g., high-pressure, sanitary, fire-safe)?

- Complete valve + actuator packages?

- Private label or OEM manufacturing?

- Global logistics and DDP delivery?

Defining your scope will screen out suitable suppliers at an early stage.

2) Consider Volume and Frequency

Are you buying:

- A one-time project quantity?

- Monthly replenishment for maintenance inventory?

- Full-line supply for system integrators or EPC projects?

High-volume customers need scalable production capacity and inventory management, and one-time customers need responsive quoting and flexible MOQ.

3. Evaluate the Supplier’s Industry Focus and Product Range

Not all valve suppliers are created equal. Some excel at low-cost mass production, others at highly engineered solutions.

1) Match Supplier Strengths to Your Industry

Choose a supplier that has experience in your vertical. For example:

- Pharmaceuticals: needs hygienic design, orbital welding, and FDA-compatible materials

- Food and beverage: requires 3-A, EHEDG certification, and CIP-compatible design

- Oil and gas: needs API 6D/607, high-pressure classes, and fire-safe testing

- Water systems may prioritize WRAS, low-lead materials, or corrosion resistance

Suppliers with industry experience will be familiar with your regulatory landscape and process requirements.

2) Consider the Entire Product Range

Is the supplier able to provide:

- A variety of valve types (ball, butterfly, globe, gate, check, diaphragm)

- Actuators (pneumatic, electric, hydraulic)

- Accessories (limit switches, solenoids, positioners)

- Custom manifolds or assemblies

An extensive product line makes sourcing, integration easier and minimizes future logistics issues.

4. Assess Manufacturing and Quality Capabilities

Valves may look good in a catalog but not perform well in the field. Look into how the valves are built.

1) Ask About the Manufacturing Plant

- Is it company-owned or subcontracted?

- How many of their own CNC machines and test benches do they utilize?

- Do they control casting, machining, assembly, and testing?

- Is there a cleanroom or sanitary assembly area available?

Vertical integration and factory ownership enhance product consistency and lead time.

2) Inquiry on Testing Procedures

Reputable suppliers test all valves before shipping. Inquire about:

- Pressure test specifications (API 598, ISO 5208)

- Leakage class conformity

- Seat and shell test procedures

- Actuator function tests

- Test documentation (FAT reports, inspection records)

You may also request third-party audits or video walk-throughs for confirmation.

5. Verify Certifications and International Compliance

Make sure your supplier carries certifications relevant to your market and applications.

Common Certifications Include:

- ISO 9001 / ISO 14001: Quality and environmental management

- API 6D / 607: Pipeline and fire-safe valves

- CE / PED: EU pressure equipment mandatory

- FDA / 3-A / EHEDG: Food-grade applications

- WRAS / ACS: Drinking water certification

- ATEX / IECEx: Explosive environment compliance

- UL / CSA: North American building and fire systems

Order certificates with up-to-date dates of validity. Non-compliant valves can lead to delays in approval or even prosecution.

6. Evaluate Engineering Support and Technical Resources

Leading suppliers don’t just sell valves—they solve problems.

1) Technical Support Capabilities

- Do they provide selection support based on your system requirements?

- Can they modify or tailor standard products?

- Do they provide CAD drawings, data sheets, and manuals?

- Can they help with flow rate calculations, Cv, or pressure drop calculations?

2) Value-Added Services

- Valve automation (actuator mounting, wiring, control logic)

- Testing customization (cryogenic testing, clean room packaging)

- Private labeling or branding

- Aftermarket retrofits and upgrades

These services reduce engineering effort on your part and streamline your procurement.

7. Evaluate Communication, Quoting, and Lead Time Transparency

Good suppliers don’t just make products—they make trust.

Look For:

- Prompt, clear RFQ responses

- Pricing transparency, including tooling, freight, and taxes

- Practical and honest lead time quoting

- Willingness to handle phased or expedited shipments

- Proper documentation (PI, B/L, COO, test reports)

Technically, ignoring or overpromising suppliers is are warning sign.

8. Assess After-Sales Support, Spare Parts, and Warranty

Your business connection with a valve supplier must last for years, not weeks.

Ask About:

- Warranty terms (what’s covered, and for how long)

- Spare part availability for 5–10 years

- Seal kits, actuator components, and trim replacement

- Online or hotline technical support

- On-site troubleshooting or the presence of distributor networks

- Maintenance training or manuals

Even quality valves need maintenance. Opt for a supplier who thinks in the long term.

9. Cross-Check Reputation and Reliability

Last but not least, do your research. Even suppliers with a good appearance can fail when it counts.

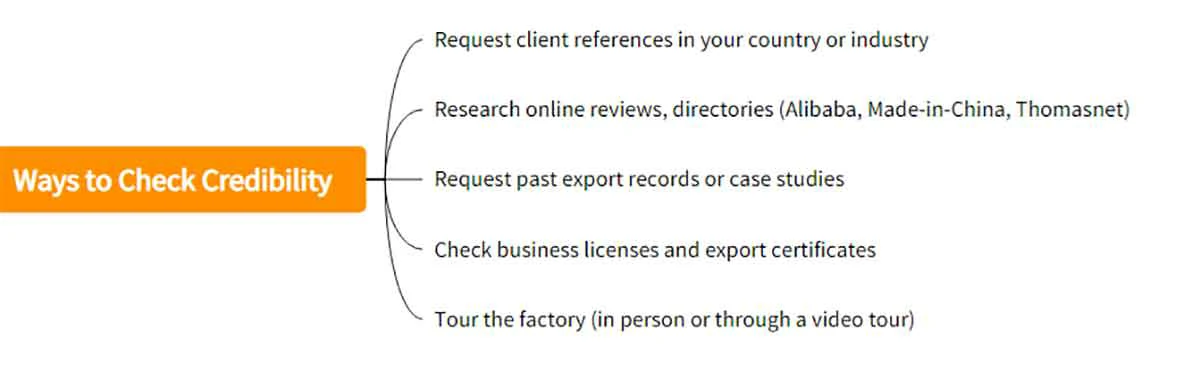

Ways to Check Credibility:

- Request client references in your country or industry

- Research online reviews, directories (Alibaba, Made-in-China, Thomasnet)

- Request past export records or case studies

- Check business licenses and export certificates

- Tour the factory (in person or through a video tour)

If feasible, test the waters with a trial order before committing to a long-term contract.

10. Balance Price, Quality, Risk, and Relationship

Price is important—but don’t make it your sole consideration. Think about the cost of ownership, including:

- Product lifespan

- Frequency of maintenance

- Risk of downtime

- Risk of compliance issues

- Speed and quality of support

- Ease of upgrade down the road

The cheapest valve can be the most expensive if it fails prematurely or shuts down your process.

11. Conclusion

The choice of a valve supplier is a strategic decision. More than part numbers and specifications, you’re looking for a partner that understands your requirements, delivers repeatable quality, supports your operations, and grows with your business.

By placing engineering capability, certification readiness, communication clarity, and after-sales reliability at the forefront of your priorities, you’ll save money on errors and achieve a competitive advantage in your market. Tip: Choose a supplier as you would hire a key employee. Look for alignment, competency, reliability—and the potential for a long-term relationship.