In today’s global food chain, food processing machinery plays a central role in making food products easily produced, safely controlled, and evenly delivered to consumers worldwide. From factory bakeries and frozen food plants to soft drink bottle lines and snack food facilities, these machines are the center of every modern food manufacturing facility.

This comprehensive guide will cover the fundamentals of food machinary, including its definitions, structures, advantages and disadvantages, primary uses, frequent questions, and future trends in the industry. You’re an entrepreneur, food technologist, or simply curious about how your food is made; this piece is written for you.

1. What is Food Processing Machinery?

Valuing its importance begins with recognizing the objective and scope of food processing equipment.

1) Basic Definition

Food processing equipment is all the appliances and apparatus that play a part in processing raw agricultural products into processed foodstuffs. The equipment is used in various processes, including:

- Mechanical processing (e.g., cutting, grinding, mixing)

- Thermal processing (e.g., baking, boiling, freezing)

- Chemical processing (e.g., fermentation, marination)

- Packaging and labeling

Whether frozen dumplings, bottled drinks, or sliced bread, machines of some form are utilized to automate and rationalize the operation.

2) Historical Background

Food processing, of course, has long used tools—grinding stones and hand mills were some of the earliest. But the industrial revolution ushered in a big change, with steam- and then electric-powered machinery. Current systems, of course, employ automation, robotics, and even artificial intelligence for optimizing and simplifying production.

2. Structure and Parts of Food Processing Machinery

Regardless of size or complexity, food processing machinery typically consists of different main parts that work cooperatively to perform certain functions.

1) Input Mechanisms

- Feed Hoppers: They are containers or cones that receive raw material (e.g., vegetables, meat, grains).

- Conveyors: Transfer ingredients from one station to another, often from machine to machine.

- Sensors: For weighing, contamination checking, or quantity control.

2) Processing Mechanisms

The “heart of the machine,” processing elements differ by function:

- Cutting blades for vegetables or meat

- Mixing paddles or augers for batter and dough

- Heating elements for steaming or baking

- Cooling plates or compressors for frozen foods

These units are generally kept inside stainless steel housings to preserve cleanliness and stability of temperature.

3) Control Systems

Advanced equipment features:

- Touch panel controls for operational control on a day-to-day basis

- PLC blocks to automate

- IoT sensors for monitoring, recording temperature, and error registration

Certain advanced systems utilize AI for real-time regulation of processing conditions for improved efficiency and product quality.

4) Output and Packaging

Half-process or ready food products are conveyed to:

- Conveyor belts

- Vacuum sealers

- Automatic tray filling or bagging

- Labeling and coding stations

This offers a seamless transition to the ultimate packaging phase without contamination.

5) Sanitation and Maintenance Access

All machinery must have:

- Rapid-disassembly components

- Clean-in-place (CIP) systems

- Drainage ports

These are required for regular sanitation, especially in dairy or meat plants.

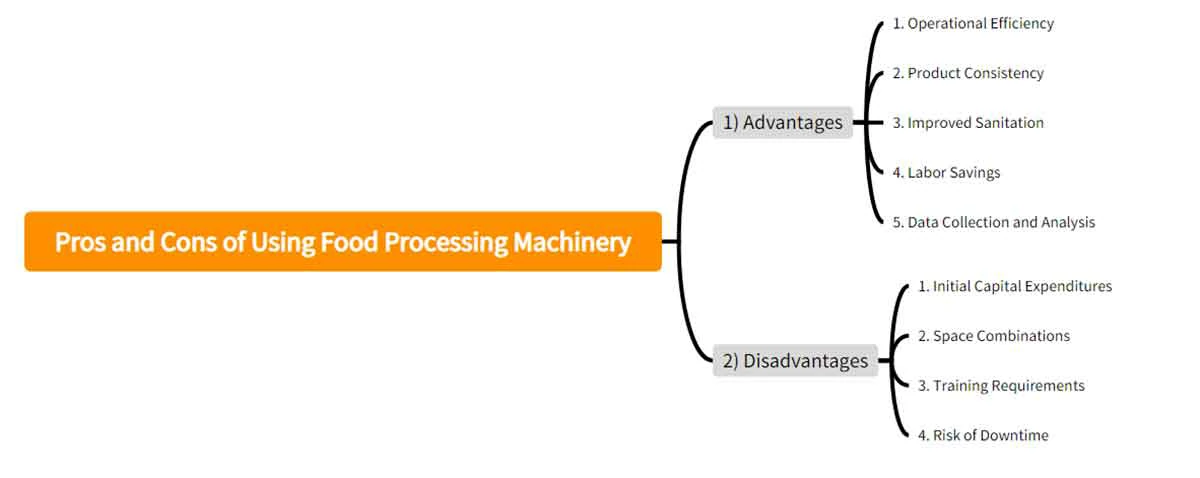

3. Pros and Cons of Using Food Processing Machinery

While these machines bring significant value to food manufacturers, they also come with certain limitations.

1) Advantages

1. Operational Efficiency

Machines can operate 24/7, reducing production time and improving output. Some high-speed lines process thousands of units per hour, far beyond what manual labor can achieve.

2. Product Consistency

Automation ensures uniformity in ingredient proportions, temperature control, and appearance—key for branding and consumer trust.

3. Improved Sanitation

Stainless steel components, sealed systems, and automation reduce the contamination threat, resulting in enhanced food safety and regulatory compliance like HACCP or FSMA.

4. Labor Savings

Replacing manual repetitive jobs eliminates the requirement for manpower, especially in high-wage countries or labor-short nations.

5. Data Collection and Analysis

New machines give real-time production data, which allows manufacturers to maximize energy usage, recognize waste, and improve line performance.

2) Disadvantages

1. Initial Capital Expenditures

Basic machinery can cost a lot of money. Advanced lines can be millions, technology and capacity permitting.

2. Space Combinations

Large machines or production lines occupy much space, which the small producer or startup may not have available.

3. Training Requirements

Operators must understand mechanical operation and electronic interfaces. Maintenance staff must be trained to repair complex systems.

4. Risk of Downtime

If a single essential machine fails, the whole line can be brought down. Preventive maintenance routine and spare units are hence critical.

4. Industry Applications and Real-World Use Cases

The versatility of food processing machinery leads to its application in almost every food category.

1) Baking and Confectionery

- Dough mixers and laminators process pastry and bread doughs.

- Depositors fill cookies, muffins, or candies with accurate filling.

- Cooling tunnels and enrobing machines enrobe chocolates or snacks.

2) Meat and Poultry

- Meat grinders and portioning machines make sausages and burger patties.

- Injectors and tumblers uniformly distribute marinades.

- High-pressure processors (HPP) enhance shelf life without additives.

3) Fruits and Vegetables

- Optical sorters inspect for shape, color, or defects.

- Blanching machines tenderize vegetables before canning or freezing.

- Pureeing machines make baby food or sauces.

4) Dairy and Cheese

- Pasteurizers heat milk to safe temperatures.

- Homogenizers prevent cream separation.

- Curd cutters and cheese molders help form and portion different varieties of cheese.

5) Beverage and Bottling

- Soda or flavored drink mixing and carbonation systems.

- Filling and capping lines maintain pressure and cleanliness in bottling.

- Labeling and shrink-wrap units automate end packaging.

6) Frozen and Ready-to-Eat Meals

- Tray sealing machines

- Tunnel freezers

- Microwave sterilizers

- These systems offer shelf stability and convenience.

5. Most Frequently Asked Questions About Food Processing Machinery

Q1: How do I choose the right machine?

Define your production needs:

- What product are you manufacturing?

- How many volume do you expect per hour?

- What budget do you have available?

- What certifications do you require in your target market?

- Ask for demonstrations, case studies, or even pilot runs.

Q2: May I start with small equipment?

Yes. Most dealers offer mini units or tabletop sizes for pilots or beginning to establish. You can grow later without overcapitalizing in the initial stages.

Q3: What is the average life of a machine?

Machines have an average life of 10–20 years with maintenance. Major wear parts like blades or seals would be replaced every 1–2 years depending on usage.

Q4: Are there turnkey machines?

Some multifunctional equipment can serve mixing + forming + packaging, especially for snack and bakery products. However, large factories prefer dedicated machinery for efficiency.

Q5: How do I maintain hygiene and compliance?

Look for:

- Stainless steel (304/316) manufacturing

- Smooth surface with crevice-free finish

- CIP (Clean-In-Place) facilities

- CE, UL, FDA, NSF, or ISO 22000 certifications

6. New Trends in Food Processing Equipment

In reaction to the evolving sustainability, labor, and global competition issues confronting food manufacturers, equipment is evolving at a rapid rate.

1) Intelligent Automation and Artificial Intelligence

AI-powered systems can:

- Avoid machine failures

- Adjust recipe parameters with sensor feedback

- Eliminate waste with real-time defect detection

2) Green Processing

- Low-energy ovens

- Water-saving washers

- Eco-packaging integration

These technologies allow companies to meet ESG goals and reduce utility bills.

3) Modular and Custom Designs

Manufacturers are increasingly fond of modular machines that can be reconfigured or upgraded as production needs change—ideal for R&D labs or startups.

4) Robotics and Cobots

Robot arms and cobots (collaborative robots) carry out operations like:

- Delicate packaging (e.g., eggs, pastry)

- High-speed pick-and-place

- Hygiene-sensitive applications

These systems reduce labor demands and improve precision.

7. Conclusion

Food processing machines are not only a luxury, but a requirement of the new food economy. They enable manufacturers to deliver safe, high-quality, and affordable food to millions of people every day. Whether enhancing shelf life and cleanliness or offering consistency and efficiency, these machines are changing the way we think about food production.

Whether a soon-to-be food business owner or a plant production manager, a basic understanding of food processing machines gives you the power to make better, greener, and more lucrative decisions. As the industry becomes more automated, digitized, and sustainable, staying ahead of machine advancements will be the key to staying competitive in the global food sector.