Passing a factory audit is likely the most important—and stressful—accomplishment of running a food manufacturing business. Whether you’re under inspection by a regulatory body, a large chain customer, or a third-party certification organization, the requirements are stringent and unyielding. And there is a powerful (but underappreciated) partner in this pursuit: your food equipment manufacturer.

The proper machinery supplier doesn’t just provide you with gear—rather, they can help you pass audits through hygienic design, provide you with compliance reports, help with traceability, and even assist in risk assessments and running procedures.

In this article, we look at how food machine manufacturers can help with audit readiness and what you require from them before, during, and after an inspection.

1. Audits and Food Equipment: What’s the Connection?

Food factory audits establish your plant’s ability to produce safe, consistent, and legally compliant food products. Document, training, and sanitation processes are overwhelming issues, yet food equipment design, installation, and maintenance are major deciding factors of audit success.

Auditors typically inspect:

- Food contact materials and hygienic design

- Machines’ cleanability and inspection access

- Preventive maintenance records

- Measuring instrument calibration records

- Safety devices (e.g., interlocks, guards, alarms)

- Product traceability and process control

- Risk assessment documentation

Your equipment supplier has direct control over most of these, so they are a key stakeholder in the audit.

2. Hygienic Design: The Key to Audit-Ready Equipment

Equipment design that creates hygiene hazards is one of the primary causes of food factories failing audits. The good news is that most qualified food equipment suppliers design their machines to international food safety standards.

1) Smooth Surfaces with Low Risk of Contamination

The equipment should be made of smooth, food-grade stainless steel (usually 304 or 316L), with smooth welds, smooth edges, and no crevices where food particles will accumulate. Your trusted supplier should supply surfaces that come into contact with foods that are easy to clean and sanitize.

2) Easy Cleaning and Inspection Access

Audit-friendly equipment contains rapid-release components, lift-off doors or covers, or tool-free access points that enable cleaning crews and inspectors to open and examine internal areas. This prevents the possibility of contamination while simplifying cleaning and verifying.

3) CIP/COP Compatibility

If your production line uses Clean-in-Place (CIP) or Clean-out-of-Place (COP) systems, machines must be compatible with these protocols. A supplier that understands these requirements will provide drainage designs, spray ball locations, and cleaning validation support.

3. Documentation That Proves Compliance

Auditors expect thorough documentation for every part of your operation, including the machines. A professional supplier can make this process easier by providing the technical paperwork you’ll need to pass inspections.

1) Material Compliance Certificates

Your auditor may require proof that all food-contact components of your equipment comply with FDA, EU 10/2011, or NSF standards. Your supplier should be able to provide material certificates, batch traceability, and component datasheets to establish compliance.

2) CE, UL, and ISO Certifications

Compliance with safety and electricity is just as important. A good supplier should be able to provide certificates proving the machine complies with standards like:

- CE marking (European Economic Area)

- UL or ETL listing (USA/Canada)

- ISO 9001 (quality management)

- ISO 22000 or FSSC 22000 (food safety management)

These reports most often form part of your factory technical file—a critical audit component.

3) Operation, Maintenance, and Calibration Manuals

Preventive equipment maintenance and calibration are always audit checklist items. Your machinery manufacturer should provide:

- A maintenance schedule in detail

- Instructions for the calibration of installed sensors or controls

- Operator manuals with safe use and cleaning procedures

Having these documents on hand makes it easier to prove your systems are well-managed and up to date.

4. Machinery Features That Support Food Safety Protocols

Equipment doesn’t just need to look clean—it needs to support consistent, safe operations under all conditions. Reputable suppliers design their machines to meet audit expectations not only through hygiene, but also through safety, traceability, and control.

1) Integrated Safety Features

Auditors expect physical safeguards like:

- Emergency stop buttons

- Interlock systems on guards and hatches

- Light curtains and sensor-based shutdowns

If your machine lacks these features, it might need expensive changes before it can succeed in a safety audit. Opt for suppliers who design with these requirements integrated.

2) Allergen and Contamination Control

Cross-contamination is a significant issue during audits, particularly in facilities that handle allergens, meat, or dairy.

Suppliers can assist by:

- Designing machines with quick changeover capabilities

- Offering dedicated tools or color-coded components

- Supplying segmented zones in the same equipment for various product lines

These capabilities help you develop SOPs that facilitate allergen control, now emphasized more than ever by auditors.

3) Traceability and Automated Recordkeeping

Certain sophisticated equipment contains sensor systems or PLC interfaces that log process parameters like temperature, time, and batch numbers. These systems generate traceable records, which are essential during audits, especially for GFSI-aligned ones like BRCGS or SQF.

5. Certification and Audit Preparation Assistance

Experienced machinery producers don’t just deliver machines—they often assist buyers with their certification process, particularly when you’re preparing for BRCGS, IFS, FSSC 22000, or HACCP certification.

1) FAT (Factory Acceptance Test) Documentation

Some suppliers offer a Factory Acceptance Test (FAT) upon delivery, explaining that the machine performs as expected. Such documentation can assist in installation qualification (IQ) and operational qualification (OQ) documents.

2) Risk Assessment Input

For those certifications that include a thorough hazard or equipment risk assessment, suppliers can assist with:

- Equipment-specific HACCP risk mapping

- Failure mode and effect analysis (FMEA)

- CCP (Critical Control Point) identification

Your supplier is integrated into your food safety plan by being included in your documentation.

3) SOP and Cleaning Protocol Support

World-class manufacturers can even provide cleaning guides, sanitation steps, and visual cleaning maps to allow your sanitation staff to create audit-ready standard operating procedures (SOPs).

6. What to Ask Your Equipment Supplier Before an Audit

So that your supplier is audit-friendly, ask the following questions:

- Will you provide us with material certificates for food contact parts?

- Are machines constructed to EHEDG, 3-A, or NSF hygiene standards?

- Do you provide CE/FDA/UL/ISO certificates?

- Can you help us prepare a preventive maintenance plan?

- Will your personnel support us during validation or inspection when needed?

Slow or document-less suppliers may not be the best choice for highly regulated manufacturing plants.

7. Choosing a Supplier That Supports Compliance

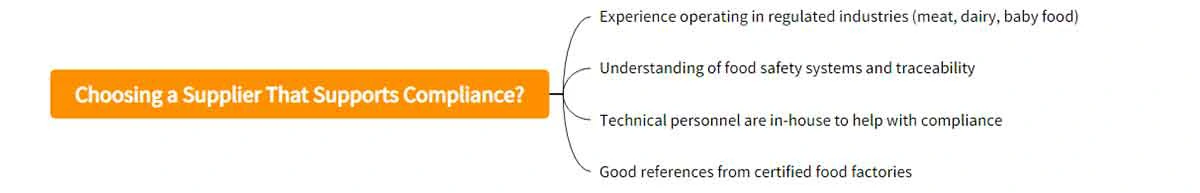

Audit-focused buyers ought to choose machinery suppliers who possess:

- Experience operating in regulated industries (meat, dairy, baby food)

- Understanding of food safety systems and traceability

- Technical personnel are in-house to help with compliance

- Good references from certified food factories

Don’t be afraid to ask for audit support as part of your purchasing requirements.

8. Conclusion

Factory inspections are grueling, but with the proper food equipment partner, they’re also much easier. From clean design and paperwork to traceability from the digital age and SOP assistance, your equipment maker can be one of your greatest assets in beating inspections and achieving certifications.

When considering food machinery, don’t simply ask: “How fast does it operate?”Also inquire: “Will this aid me in passing my next inspection?”