Designing a food processing line is not just about buying the right machines. It’s about how these machines fit, connect, and flow in your actual workspace. Many factories make the mistake of selecting equipment first and then trying to force it into a space that doesn’t match the workflow. The result? Inefficiency, safety hazards, compliance issues, and wasted labor.

This guide walks you through how to customize a food processing line based on your unique factory layout, ensuring smooth operations, better sanitation, and long-term scalability. Unlike equipment selection, troubleshooting, or importing, which we’ve discussed in previous articles, this article focuses specifically on layout-driven planning and integration.

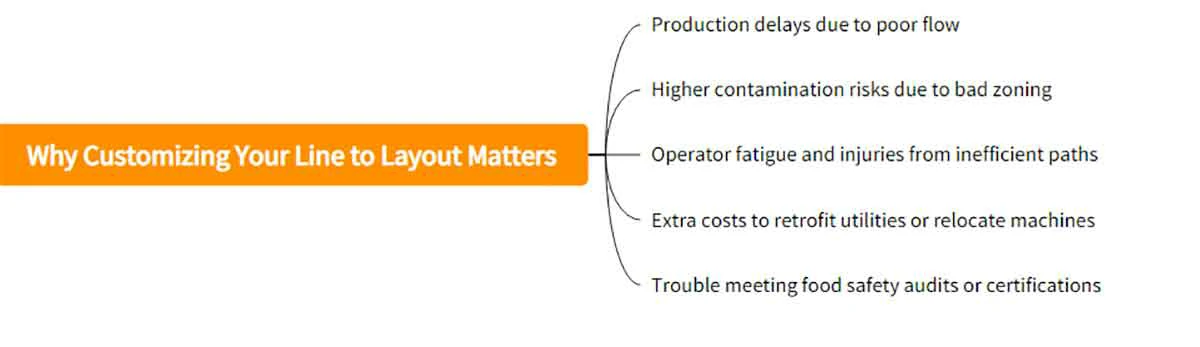

1. Why Customizing Your Line to Layout Matters

Your physical plant space isn’t just an empty shell—it’s a critical design constraint. Ignoring it can result in serious consequences:

- Production delays due to poor flow

- Higher contamination risks due to bad zoning

- Operator fatigue and injuries from inefficient paths

- Extra costs to retrofit utilities or relocate machines

- Trouble meeting food safety audits or certifications

A layout-informed production line helps ensure food safety, energy efficiency, employee productivity, and future flexibility.

2. Understand Your Food Production Flow First

Before thinking about machine placement, define your product’s production journey. A food processing line should follow a logical, linear path from raw material intake to final packaging.

1) Map Out Process Stages

Each factory is unique, but most food processing lines go through the following steps:

- Raw material receiving and storage

- Washing or sorting (fruits, vegetables, meats)

- Mixing, blending, or marinating

- Forming or shaping

- Cooking, baking, steaming, or freezing

- Cooling and drying

- Packaging and sealing

- Labeling and cartoning

- Storage and dispatch

Knowing exactly where each stage starts and ends allows you to configure machinery in sequence, avoiding inefficient loops or cross-contamination.

2) Apply Unidirectional Product Flow

Food safety authorities and global standards (like BRC, FSSC 22000, or HACCP) require unidirectional movement—raw materials should never cross paths with finished goods. Your layout should support this clean-forward logic.

3. Assess Your Actual Space and Physical Constraints

Once your process flow is clear, measure your factory and identify obstacles and limitations.

1) Floor Plan Dimensions

Measure usable space, including:

- Total floor area (length × width)

- Clearance height (especially important for mixers, silos, or spiral conveyors)

- Aisle widths for people and trolleys

- Loading dock access for raw materials and finished goods

2) Utilities and Infrastructure

Machine operation depends on access to power, air, water, and drains. Map out:

- Electrical panels and voltage availability (e.g., 220V, 380V)

- Compressed air line locations

- Water inlets, steam pipes, and floor drains

- Ventilation hoods or exhaust ducts

It’s much more economical to adapt the machine to fit existing infrastructure than to rewire your factory.

3) Floor Strength and Surface Type

Heavy machinery (like industrial fryers or cookers) can exceed 1,000 kg. Be sure your floors can support the load. Also, verify that floor coatings are non-slip, waterproof, and resistant to food acids or grease.

4. Collaborate with Equipment Manufacturers for Layout-Friendly Designs

A professional food processing machine manufacturer will help adapt their standard machines to your layout. Don’t hesitate to ask for layout-specific customization.

1) Request Scaled CAD or 3D Models

Most industrial suppliers can provide .dwg or .step files for each machine. These files can be imported into your factory layout plan to test spacing, flow, and utility connections.

2) Mirror or Flip Configurations

Machines like dough formers, slicers, or depositors often have left-hand and right-hand versions. Confirm that the discharge end matches your desired flow direction.

3) Combine or Stack Functions

In tight spaces, ask if the supplier offers compact or integrated models, such as:

- Mixer + conveyor on one frame

- Oven + spiral cooler combo

- Vertical tray fillers to save footprint

These integrations are especially helpful for startups or urban production sites with space constraints.

5. Design for Operator Workflow and Safety

A good layout doesn’t just serve machines—it supports people too.

1) Separate Operator Zones and Walkways

Avoid positioning machines too close together. Maintain:

- At least 80 cm between machines for cleaning access

- 1.2 meters for walkways with two-way traffic

- Designated crosswalks with floor markings for high-traffic areas

2) Avoid Cross-Contamination Paths

Use layout to separate:

- Raw and cooked products

- Allergen-free and allergen-containing zones

- Employees from different departments (e.g., mixing vs. packing)

These precautions are not just good practice—they’re often audit requirements.

3) Position Control Panels Accessibly

Control panels should be:

- On the side facing operators

- Away from steam or moisture zones

- Not blocked by mobile carts or racks

This improves safety and response time in case of alarms or machine stops.

6. Include Sanitation and Cleaning Considerations

Hygienic design isn’t just about equipment. Your layout must make cleaning easy and effective.

1) Leave Clearance Around Machines

At least 50–80 cm clearance should be left around heavy machinery for:

- Pressure washing

- Visual inspections

- Pulling equipment out for deep cleaning

2) Drainage and Slopes

If the process involves water or liquid ingredients:

- Ensure floors slope toward drains (about 1–2%)

- Place trench drains near wet machines (e.g., vegetable washers or sauce mixers)

- Avoid pooling by inspecting the drain placement in your layout

3) Detergent and Chemical Access

Designate space for cleaning supply storage and hose connections near processing areas. Centralized CIP systems should have reach to all relevant units.

7. Ensure Regulatory and Workflow Compliance

Regulatory audits often review your physical layout for safety, efficiency, and hygiene. You can design your line to meet these expectations from day one.

1) HACCP and GMP Principles

A good layout helps control:

- Critical Control Points (e.g., cooking temperature verification)

- Airflow between zones

- Pest prevention (through physical barriers and sealed entryways)

Document your layout in your HACCP plan and flowchart.

2) Fire and Emergency Safety

Leave space for:

- Fire extinguishers and alarms

- Emergency doors that aren’t blocked

- Emergency stop buttons reachable within 1.5 meters of the operator stations

Ensure emergency lighting is visible and functional along major walkways.

8. Plan for Expansion and Flexibility

Design your layout with future growth in mind—even if you’re starting small.

1) Modular Line Configuration

Use modular conveyors, mobile tables, and wheeled equipment where possible. This makes it easy to:

- Add machines later

- Rearrange the flow as product lines expand

- Clean and maintain individual sections

2) Reserve Empty Zones

Leave some unoccupied areas near:

- Packaging stations (to add auto-labelers or weight checkers later)

- Mixing or forming units (to upgrade feeding systems)

- Finished goods staging areas (to add cold rooms or palletizers)

Even 10–20 square meters of reserved space can save major headaches later.

9. Conclusion

A well-customized food processing line isn’t built by simply stacking machines together—it’s the result of thoughtful, layout-driven planning. Your factory space, utilities, people, and compliance requirements should all shape how you place and configure your equipment.

By collaborating closely with equipment manufacturers, involving facility engineers early, and keeping workflow and sanitation in mind, you’ll end up with a line that not only fits—but flows. And a production line that flows is one that delivers quality, efficiency, and room to grow.